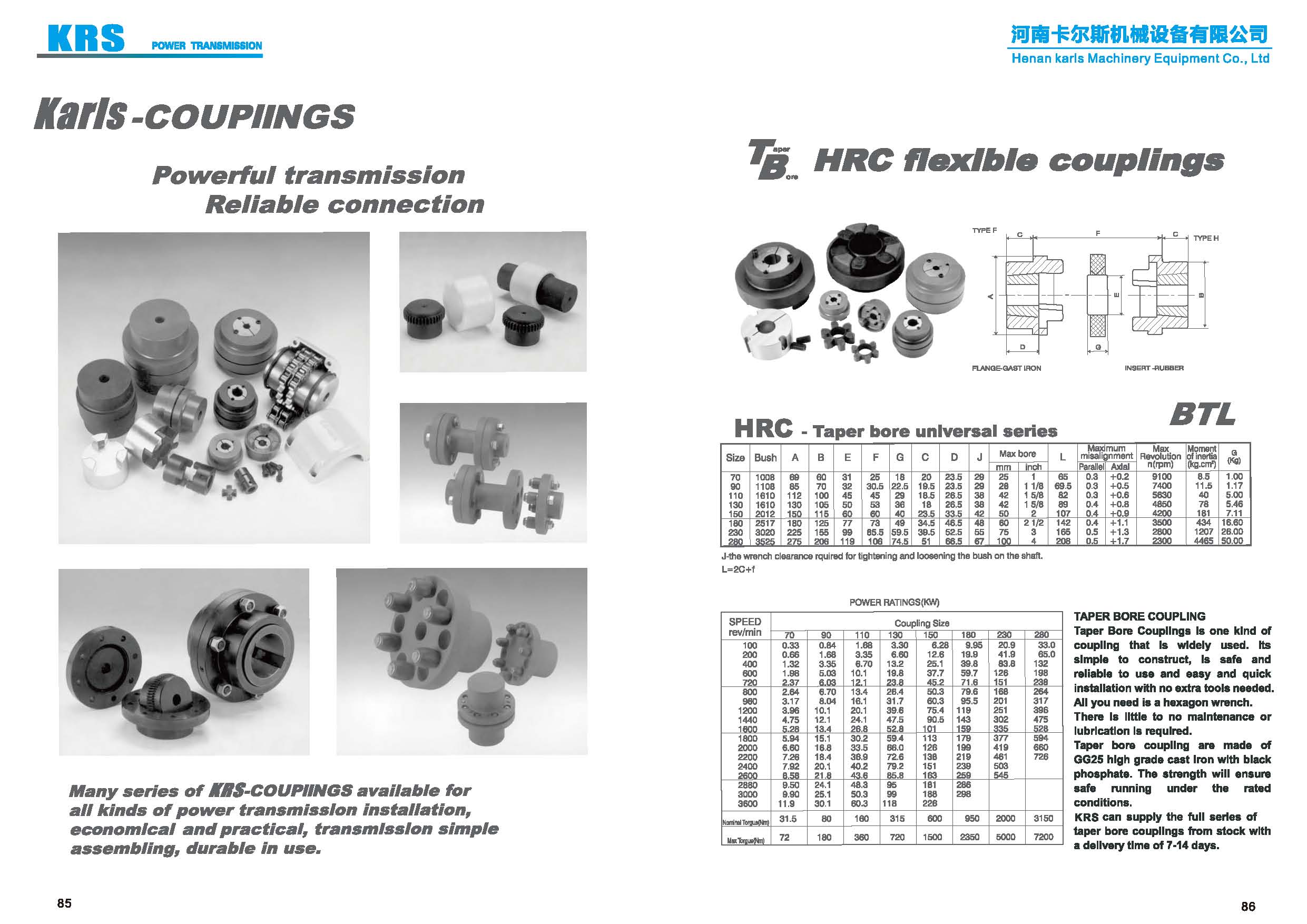

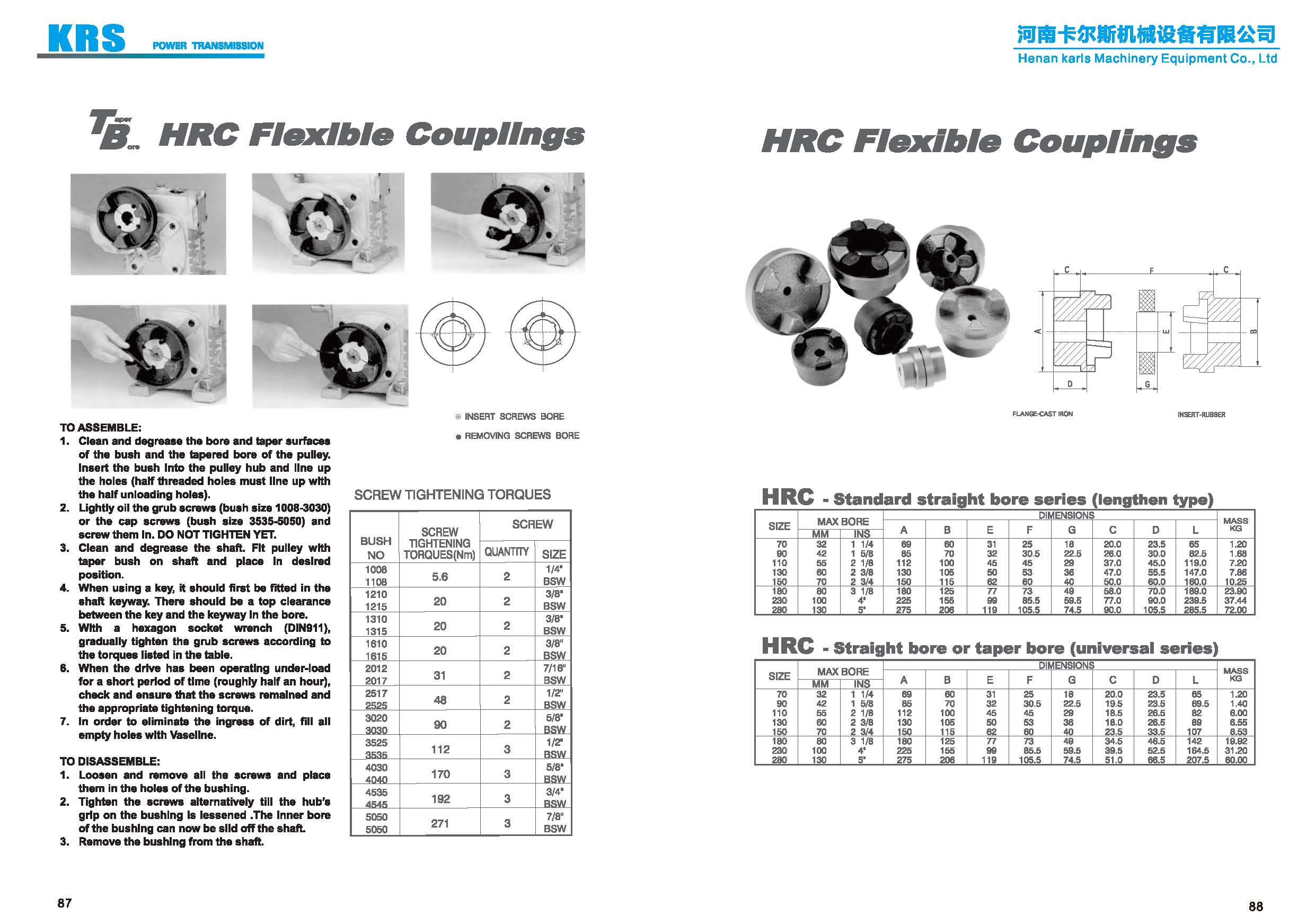

HRC Couplings are couplings for general application with a flexible element which can counterbalance higher degree of misalignment: Parallel misalignment up to 0.5 mm and Axial misalignment up to 1.7 mm. Because of their superior design HRC couplings can fit larger shafts which make them a very interesting product.

Thanks to the extensive range of products, a suitable solution is available for each particular application, because, in addition to transmitting torque, each type of shaft coupling has certain ancillary functions: torsional stiffness (important for positioning accuracy), rupture-proof (e.g. for lifting applications) or not rupture-proof, vibration-dampening (for internal combustion engines) and compensating alignment errors (parallelism errors or angle errors).

Sometimes the installation options also play a role (e.g. mounted axially or radially). If the situation requires it, shaft couplings can also be counterbalanced. If a distance must be bridged between the shafts, components known as spacer couplings can be used. The shaft offset is often referred to as DBSE (distance between shaft ends).

There are also shaft couplings that can be used at high ambient temperatures (e.g. couplings completely made from metal) or in potentially explosive areas where the components must meet the FRAS and/or ATEX guidelines.

Shaft couplings can be found in virtually every industry: (petro)chemicals, the food and drug industries, mechanical engineering, maritime applications, and by no means least in agriculture and forestry, as well as fisheries.

Various standards are relevant for shaft couplings, for example, DIN 740, DIN 115 and DIN 116.33页

Tooth belt pulleys are generally made of steel, cast iron (GG) or aluminium. Pulleys are also available in other materials such as plastic or stainless steel for specialised applications. Of course, it is also possible to apply a particular surface treatment to the pulleys if the ambient conditions require it.

Several factors determine which toothed belt type is best suited to a particular drive, for example the application (what is being driven?), the power to be transferred, the desired speed (acceleration or deceleration) and the centre-to-centre distance between the pulleys. It is also important to know what ambient conditions are present and whether there are any space limitations (what is the maximum permissible diameter and width of the pulleys?).

Common standards for toothed belt drives are DIN 7721 and ISO 5294. Finally, it is important to consider whether the drive needs to be static-conductive to meet ISO 9563 (ATEX environments).

We support various ways for international transportation.

Customers can choose a suitable way based on their needs such as by air, by sea and by express(Fedex, DHL, TNT etc.).

If you have any enquiry about quotation or cooperation, please feel free to email us at krs186@aliyun.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

Phone/Fax

+86 0371 6505 2655Skype

+86 15670633693Address

Jinshui District Zhengzhou Henan ChinaMainly producing transmission products such as sprockets, pulleys and taper lock bushes;