Our range of products include also taperlock sprockets. These sprockets are made in C45.Karls drives are primarily used in the foodstuffs and drug industries, in the agricultural and forestry sector, in the fishing industry, in mechanical engineering and in maritime applications.

Karls Drive Principles

▶ Karls drives normally transmit power from one rotating shaft to another.

▶ Karls drives maintain a positive speed ratio between driver and driven sprockets.

▶ The driver and driven sprockets will rotate in the same direction on typical Karls drives.

▶ If the Karls has an even number of pitches, the sprockets have an odd number of teeth. If the sprockets have an even number of teeth, the Karls has an uneven number of pitches. This design feature prevents a single link from contacting the same tooth each time, causing wear and vibration.

▶ Small diameter sprockets cause the Karls to bend sharply; therefore, the Karls wears more quickly.

▶ Short Karls links bend less and should be used on small diameter sprockets.

▶ Karlss may be installed as single or multiple-strand drives, depending on speed and load.

▶ Karls slack must be adjusted periodically by shifting one of the sprockets or by using a Karls tightener.

▶ Horizontal Karls drives should have slack on the bottom (do not allow the Karls to rub on the guard or casing).

▶ Tighteners or idlers should be located on the slack side of the Karls.

We support various ways for international transportation.

Customers can choose a suitable way based on their needs such as by air, by sea and by express(Fedex, DHL, TNT etc.).

If you have any enquiry about quotation or cooperation, please feel free to email us at krs186@aliyun.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

Phone/Fax

+86 0371 6505 2655Skype

+86 15670633693Address

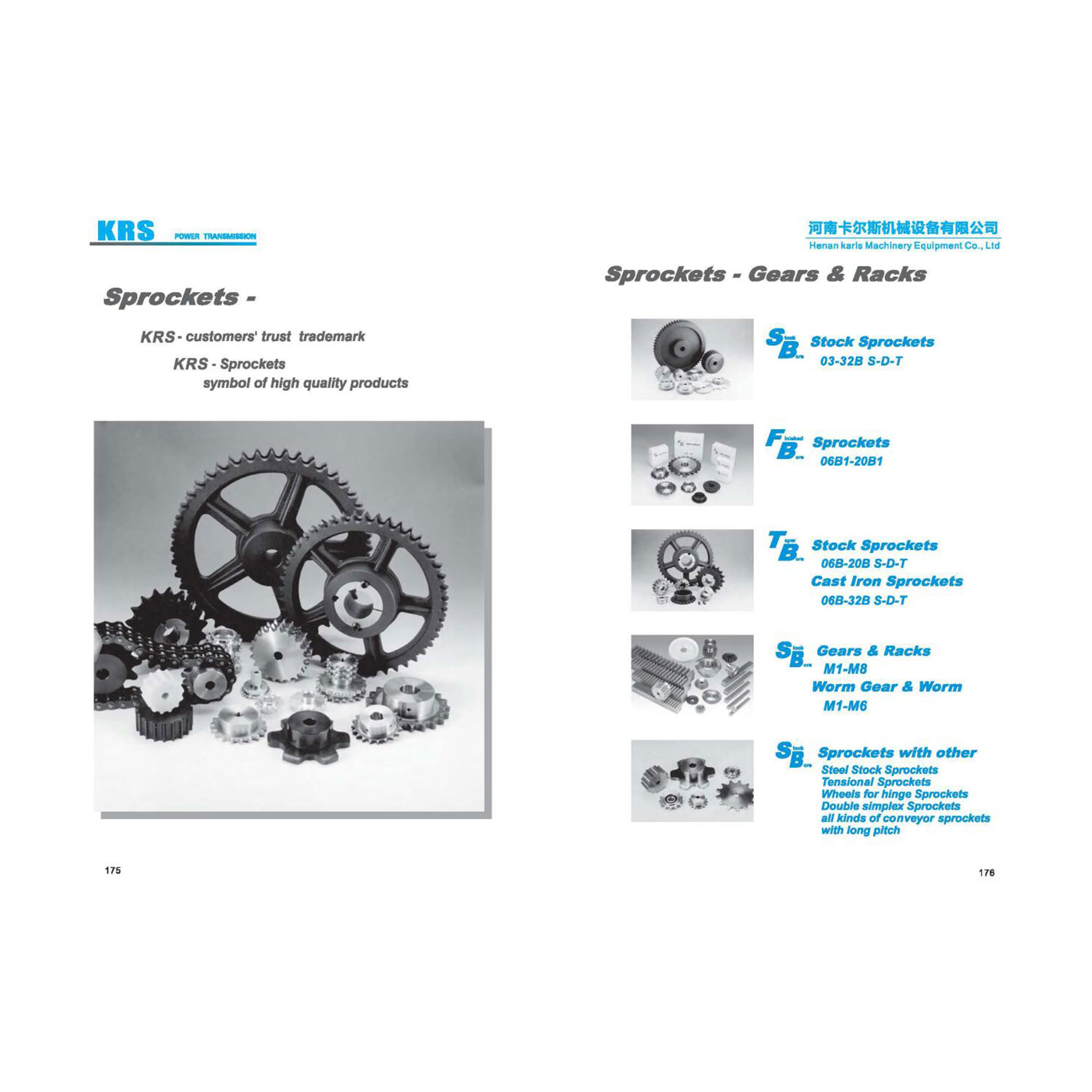

Jinshui District Zhengzhou Henan ChinaMainly producing transmission products such as sprockets, pulleys and taper lock bushes;