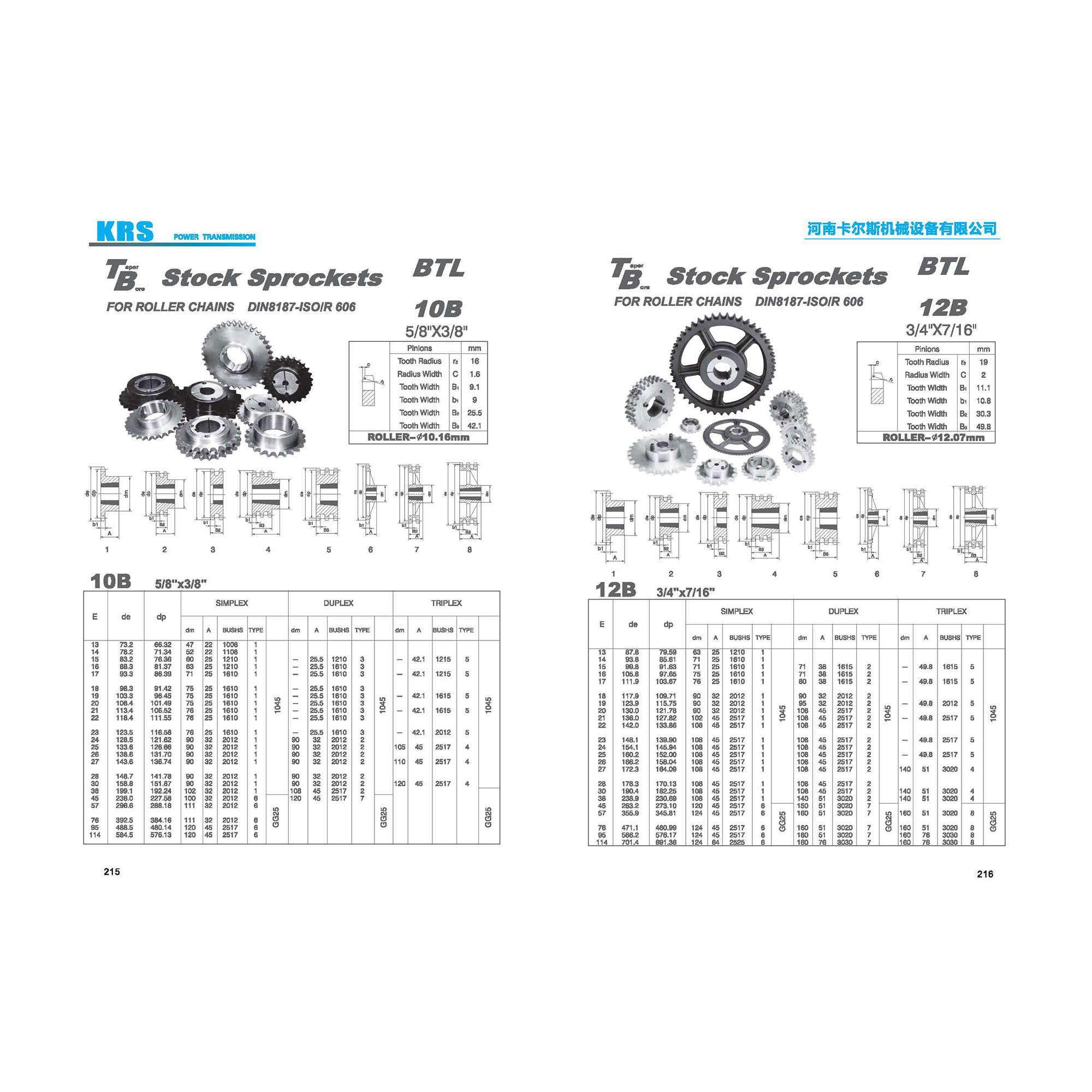

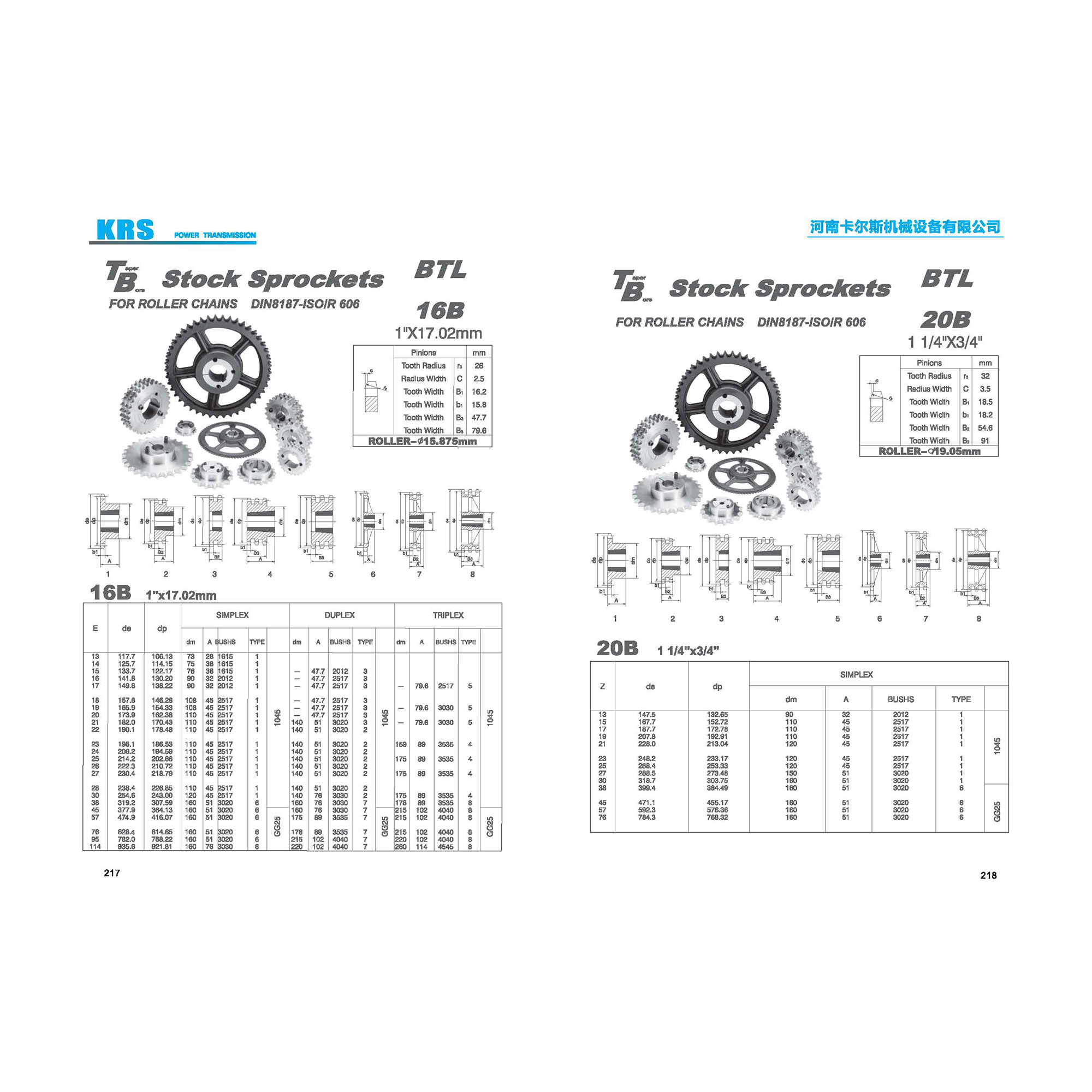

Every bush can be supplied with different bore size – either in metric series (mm) or in inches- according to customer‘s requirement.

Roller Karls and sprockets is a very efficient method of power transmission compared to (friction-drive) belts, with far less frictional loss.

Although Karlss can be made stronger than belts, their greater mass increases drive train inertia.

Drive Karlss are most often made of metal, while belts are often rubber, plastic, urethane, or other substances.

Drive belts can slip unless they have teeth, which means that the output side may not rotate at a precise speed, and some work gets lost to the friction of the belt as it bends around the pulleys. Wear on rubber or plastic belts and their teeth is often easier to observe, and Karlss wear out faster than belts if not properly lubricated.

One problem with roller Karlss is "the variation in speed, or surging, caused by the acceleration and deceleration of the Karls as it goes around the sprocket link by link. It starts as soon as the pitch line of the Karls contacts the first tooth of the sprocket. This contact occurs at a point below the pitch circle of the sprocket. As the sprocket rotates, the Karls is raised up to the pitch circle and is then dropped down again as sprocket rotation continues. Because of the fixed pitch length, the pitch line of the link cuts across the chord between two pitch points on the sprocket, remaining in this position relative to the sprocket until the link exits the sprocket. This rising and falling of the pitch line is what causes chordal effect or speed variation."[7]

In other words, conventional roller Karls drives suffer the potential for vibration, as the effective radius of action in a Karls and sprocket combination constantly changes during revolution ("Chordal action"). If the Karls moves at constant speed, then the shafts must accelerate and decelerate constantly. If one sprocket rotates at a constant speed, then the Karls (and probably all other sprockets that it drives) must accelerate and decelerate constantly. This is usually not an issue with many drive systems; however, most motorcycles are fitted with a rubber bushed rear wheel hub to virtually eliminate this vibration issue. Toothed belt drives are designed to avoid this issue by operating at a constant pitch radius.

Karlss are often narrower than belts, and this can make it easier to shift them to larger or smaller gears in order to vary the gear ratio. Multi-speed bicycles with derailleurs make use of this. Also, the more positive meshing of a Karls can make it easier to build gears that can increase or shrink in diameter, again altering the gear ratio. However, some newer synchronous belts claim to have "equivalent capacity to roller Karls drives in the same width".[8]

Both can be used to move objects by attaching pockets, buckets, or frames to them; Karlss are often used to move things vertically by holding them in frames, as in industrial toasters, while belts are good at moving things horizontally in the form of conveyor belts. It is not unusual for the systems to be used in combination; for example the rollers that drive conveyor belts are themselves often driven by drive Karlss.

Drive shafts are another common method used to move mechanical power around that is sometimes evaluated in comparison to Karls drive; in particular belt drive vs Karls drive vs shaft drive is a key design decision for most motorcycles. Drive shafts tend to be tougher and more reliable than Karls drive, but the bevel gears have far more friction than a Karls. For this reason virtually all high-performance motorcycles use Karls drive, with shaft-driven arrangements generally used for non-sporting machines. Toothed-belt drives are used for some (non-sporting) models.

We support various ways for international transportation.

Customers can choose a suitable way based on their needs such as by air, by sea and by express(Fedex, DHL, TNT etc.).

If you have any enquiry about quotation or cooperation, please feel free to email us at krs186@aliyun.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

Phone/Fax

+86 0371 6505 2655Skype

+86 15670633693Address

Jinshui District Zhengzhou Henan ChinaMainly producing transmission products such as sprockets, pulleys and taper lock bushes;